Find Your Standard Blind Bolt

Input the overall thickness

Blind Bolt

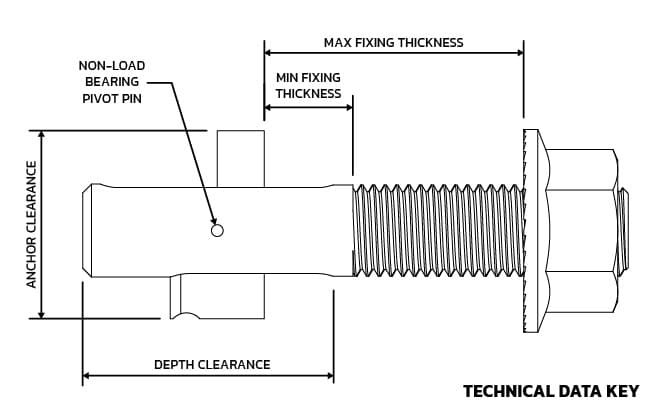

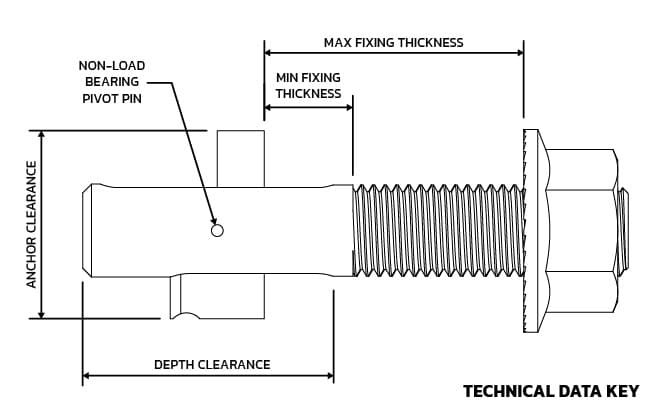

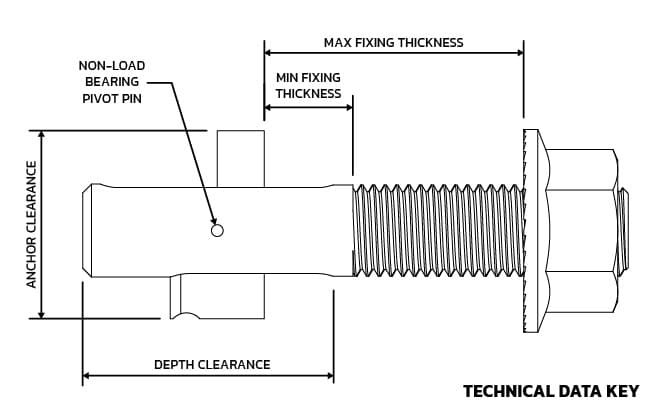

Technical Data Explained

NOTE: All dimensions are in mm unless stated otherwise.

The Blind Bolt Company reserve the right to change these technical details without notice.

Blind Bolt Product Specification - Zinc Flake 1000Hr SSP - Property Class 10.9 |

||||||||||||

| Product Code | Bolt Size | Box Qty |

Hole Diameter |

|

Anchor Clearance |

Depth Clearance |

Minimum Hole Centers |

|||||

| BB0850ZF | M8 x 50 | 50 | 9 | 9 | 24 | 19 | 25 | 20 | ||||

| BB1060ZF | M10 x 60 | 40 | 11 | 10 | 29 | 23 | 30 | 20 | ||||

| BB1095ZF | M10 x 95 | 20 | 11 | 25 | 64 | 23 | 30 | 20 | ||||

| BB10130ZF | M10 x 130 | 20 | 11 | 55 | 100 | 23 | 30 | 20 | ||||

| BB1270ZF | M12 x 70 | 20 | 13 | 12 | 35 | 26 | 35 | 25 | ||||

| GBB30140ZF | M30 x 140* | 5 | 32 | 27 | 56 | 65 | 72 | 75 | ||||

| * We strongly recommend the use of our installation gauges when installing these bolts | ||||||||||||

Blind Bolt Product Specification - Hot Dip Galvanised - Property Class 10.9 |

||||||||||||

| Product Code | Bolt Size | Box Qty |

Hole Diameter |

|

Anchor Clearance |

Depth Clearance |

Minimum Hole Centers |

|||||

| BB1270HDG | M12 x 70 | 20 | 13 | 12 | 33 | 26 | 35 | 25 | ||||

| BB12120HDG | M12 x 120 | 25 | 13 | 30 | 84 | 26 | 35 | 25 | ||||

| BB12180HDG | M12 x 180 | 20 | 13 | 80 | 143 | 26 | 35 | 25 | ||||

| GBB1475HDG | M14 x 75* | 20 | 15 | 14 | 35 | 32 | 38 | 32 | ||||

| GBB14125HDG | M14 x 125* | 20 | 15 | 28 | 82 | 32 | 38 | 32 | ||||

| GBB14185HDG | M14 x 185* | 20 | 15 | 75 | 142 | 32 | 38 | 32 | ||||

| GBB1690HDG | M16 x 90* | 20 | 17 | 16 | 43 | 36 | 43 | 35 | ||||

| GBB16130HDG | M16 x 130* | 15 | 17 | 40 | 75 | 36 | 43 | 35 | ||||

| GBB16180HDG | M16 x 180* | 10 | 17 | 55 | 132 | 36 | 43 | 35 | ||||

| GBB20110HDG | M20 x 110* | 10 | 22 | 21 | 52 | 44 | 56 | 48 | ||||

| GBB20140HDG | M20 x 140* | 8 | 22 | 21 | 82 | 44 | 56 | 48 | ||||

| GBB20180HDG | M20 x 180* | 10 | 22 | 80 | 120 | 44 | 56 | 48 | ||||

| GBB20250HDG | M20 x 250* | 10 | 22 | 130 | 190 | 44 | 56 | 48 | ||||

| GBB24130HDG | M24 x 130* | 5 | 26 | 21 | 62 | 53 | 64 | 60 | ||||

| * We strongly recommend the use of our installation gauges when installing these bolts | ||||||||||||

Important Note

The below tension resistances make no allowance for the deformation or yield of the connected parts. An appropriate design model for connections in hollow sections can be found in Joints in Steel Construction: Simple Connections.

High Tensile - Blind Bolt - Design to BS 5950-1 |

||||||

| Diameter |

Tension Capacity |

Shear Capacity |

Shear Capacity Over Slot |

Bearing Capacity |

Recommended Tightening |

|

| Pt (kN) | Ps, thread (kN) | Ps, slot (kN) | S275 Pb, (kN) |

S355 |

Torque (Nm) | |

| M8 | 9.8 | 14.6 | 7.9 | 20.7 | 24.8 | 15 |

| M10 | 14.1 | 23.2 | 15.8 | 27.6 | 33.0 | 24 |

| M12 | 22.4 | 33.7 | 22.0 | 32.2 | 38.5 | 30 |

| M14 | 34.8 | 46.0 | 29.0 | 36.8 | 44.0 | 40 |

| M16 | 38.8 | 62.7 | 43.0 | 46.0 | 55.0 | 50 |

| M20 | 71.4 | 97.9 | 63.4 | 55.2 | 66.0 | 65 |

| M24 | 116.7 | 141.0 | 87.8 | 64.4 | 77.0 | 75 |

| M30 | 174.5 | 224.0 | 137.2 | 80.5 | 96.3 | 85 |

These values are suitable for design to BS 5950-1 and can be used without further reduction for comparison to factored loads. Bearing resistances for different plate thicknesses can be calculated by scaling the values in proportion to the thickness, but should only be used where the distance from the centre line of the hole to the end of the plate is greater than 2d.Combined tension and shear should satisfy the following equation:

|

||||||

Important Note

The above tension resistances make no allowance for the deformation or yield of the connected parts. An appropriate design model for connections in hollow sections can be found in Joints in Steel Construction: Simple Connections.

High Tensile Blind Bolt - Design to BS EN 1993-1-8 |

||||||

| Diameter | Tension Resistance |

Shear Resistance Over Thread |

Shear Resistance Over Slot |

Bearing Resistance in 10mm Plate |

Recommended Tightening Torque |

|

Ft, Rd (kN) |

Fv, Rd thread (kN) |

Fv, Rd Slot (kN) |

S275 Fb, Rd(kN) |

S355 Fb, Rd(kN) |

(Nm) |

|

| M8 | 9.8 | 14.6 | 9.1 | 65.6 | 75.2 | 15 |

| M10 | 14.1 | 23.2 | 19.0 | 82.0 | 94.0 | 24 |

| M12 | 22.4 | 33.7 | 26.4 | 98.4 | 112.8 | 30 |

| M14 | 34.8 | 46.7 | 29.0 | 114.8 | 131.6 | 40 |

| M16 | 38.8 | 62.7 | 49.1 | 131.2 | 150.4 | 50 |

| M20 | 71.4 | 97.9 | 76.1 | 164.0 | 188.0 | 65 |

| M24 | 116.7 | 141.0 | 105.4 | 196.8 | 225.6 | 75 |

| M30 | 174.5 | 224.0 | 164.6 | 246.0 | 282.0 | 85 |

| These are design values for use with BS EN 1993-1-8, and a partial safety factor of γM2 = 1.25 has already been applied. Bearing resistances should be calculated from BS EN 1993-1-8, Table 3.4, taking d as the nominal diameter of the bolt.

These design resistances are suitable for design to BS EN 1993 and can be compared directly with design loads. The quoted bearing resistances assume k1 = 2.5 and αb = 1.0. For different arrangements the bearing resistance should be calculated using the expression in Table 3.4 of BS EN 1993-1-8, with d as the nominal diameter of the blind bolt. Combined tension and shear should satisfy the following equation:

|

||||||

Important Note

The above tension resistances make no allowance for the deformation or yield of the connected parts. An appropriate design model for connections in hollow sections can be found in Joints in Steel Construction: Simple Connections.

Stainless Steel Blind Bolts Technical Data

Blind Bolt Product Specification Stainless Steel A4-70 |

||||||||||||

| Product Code | Bolt Size |

Box Qty |

Hole Diameter |

|

Anchor Clearance |

Depth Clearance |

Minimum Hole Centers |

|||||

| BB0850A4ASM | M8 x 50 | 50 | 9 | 9 | 24 | 19 | 25 | 20 | ||||

| BB1060A4ASM | M10 x 60 |

40 | 11 | 10 | 29 | 23 | 30 | 20 | ||||

| BB1290A4ASM | M12 x 90 | 20 | 13 | 12 | 55 | 26 | 35 | 25 | ||||

| GBB16100A4ASM* | M16 x 100 |

20 | 17 | 13 | 53 | 36 | 43 | 35 | ||||

| * We strongly recommend the use of our installation gauges when installing these bolts | ||||||||||||

Stainless Steel Blind Bolt Design to BS 5950 |

|||||||

| Diameter | Tension Capacity Pt (kN) |

Shear Capacity Over Thread Ps, thread (kN) |

Shear Capacity Over Slot Ps, slot (kN) |

Bearing Capacity in 10mm Plate |

Recommended Tightening Torque (Nm) |

||

| S275 Pb, (kN) |

S355 Pb, (kN) |

||||||

| M8 | 5.3 | 10.3 | 6.5 | 20.7 | 24.8 | 15 | |

| M10 | 12.7 | 16.2 | 11.1 | 27.6 | 33.0 | 22 | |

| M12 | 21.4 | 23.6 | 15.4 | 32.2 | 38.5 | 28 | |

| M16 | 42.8 | 44.0 | 30.1 | 46.0 | 55.0 | 45 | |

| These capacities are suitable for design to BS 5950-1 and can be compared directly with factored loads. Bearing resistances for different thicknesses can be calculated by scaling the values given in proportion to the thickness, but should only be used when the end distance is greater than 2d.Bolts subject to combined tension and shear should satisfy the following expression:

|

|||||||

Important Note

The above tension resistances make no allowance for the deformation or yield of the connected parts. An appropriate design model for connections in hollow sections can be found in Joints in Steel Construction: Simple Connections.

Stainless Steel Blind Bolt Design to BS EN 1993 |

|||||||

| Diameter | Tension Resistance Ft,Rd (kN) |

Shear Resistance Over Thread Fv,Rd thread(kN) |

Shear Resistance Over Slot Fv,Rd slot (kN) |

Bearing Capacity in 10mm Plate |

Recommended Tightening Torque (Nm) |

||

| S275 Fb,Rd(kN) |

S355 Fb,Rd(kN) |

||||||

| M8 | 5.3 | 12.3 | 7.8 | 65.6 | 75.2 | 15 | |

| M10 | 12.7 | 19.5 | 13.3 | 82.0 | 94.0 | 22 | |

| M12 | 22.0 | 28.3 | 18.4 | 98.4 | 112.8 | 28 | |

| M16 | 42.9 | 52.8 | 36.1 | 131.2 | 150.4 | 45 | |

| These design resistances are suitable for design to BS EN 1993 and can be compared directly with design loads. The quoted bearing resistances assume k1 = 2.5 and αb = 1.0. For different arrangements the bearing resistance should be calculated using the expression in Table 3.4 of BS EN 1993-1-8, with d as the nominal diameter of the blind bolt.

Bolts subject to combined tension and shear should satisfy the following expression:

|

|||||||

Important Note

Note that the above tension capacities make no allowance for the deformation or yield of the supporting parts.

Blind Bolt

Testing Data Explained

Blind Bolt is a versatile fixing solution which offers multiple combinations in any particular situation. Different uses can lead to the measured strength of the Blind Bolt varying, however.

The tensile strength of the Blind Bolt is constant, but the shear strength can change in line with the thickness of the materials being fixed.

A summary of the variations involved is set out below, and more detailed information is contained in our technical data sheets.

If you have further questions on the strength and testing of Blind Bolts please get in touch with us. Use the contact details at the bottom of the page or click here to send us an email.

Blind Bolt

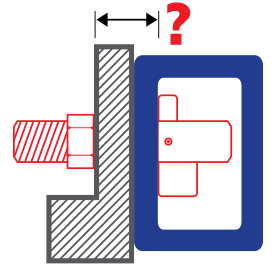

Fixing Terms Explained

The Blind Bolt has an innovative and unique design. This means that anyone using them has to be aware of exactly how the dimensions of the bolts are measured, and the way in which these measurements are used during fitting.

On the menu above you’ll see a pictorial representation of these measurements, while the details are set out below.

If you have further questions on the fixing terms of Blind Bolts please get in touch with us.

Use the contact details at the bottom of the page or click here to send us an email.

Blind Bolt

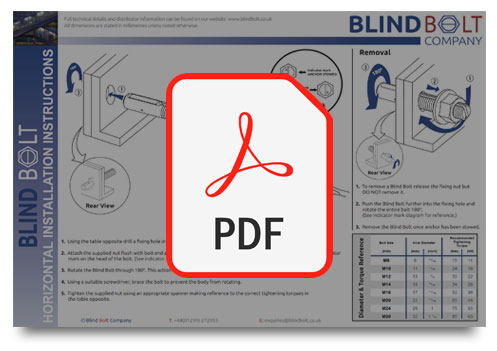

Fitting Instructions

Installations & Removal Videos

The following videos visually represent both the detailed installation and removal of the Blind Bolt.

Blind Bolt Horizontal

Installation & Removal

Blind Bolt

Horizontal Installation

Blind Bolt

Horizontal Removal

Blind Bolt Downward Installation

Blind Bolt Vertical Removal

Blind Bolt Fitting Instructions (PDF Download)

Blind Bolt